condom manufacturing process

Condom Manufacturing Process

Collecting the raw materials

1 Rubber latex is obtained from the milky fluid produced by various tropical plants. Latex is actually an emulsion or dispersion of tiny rubber particles in water, and ingredients added to the latex must be able to attach to the rubber particles during compounding.

Compounding

2 Next, chemical additives are mixed to form a paste. This paste is then blended with the liquid latex in a process called compounding.

Storage

3 The latex and chemical compound is then unloaded into drums for storage, where it remains for approximately seven days. During this period, vulcanization chemically strengthens the bonds of the rubber. The storage time also allows any

air, which might have been trapped in the mixture during compounding, to escape.

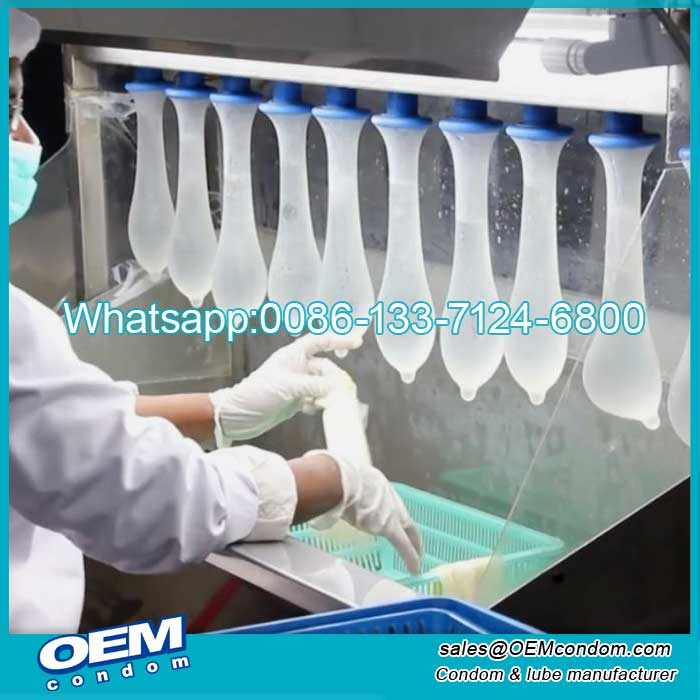

Dipping

4 The compound is then added to the dipping or condom-forming machine. The dipping machine is a long, hooded machine approximately 100 feet (30.5 m) in length. Thick tempered glass rods move along a closed belt between two circular gears. The belt drags the rods, which are called mandrels, through a series of dips into the latex compound. The mandrels rotate to spread the latex evenly. Several coats are required to build the condom to its required thickness. Between each dip, the latex is hot air dried.

5 After the final dipping and drying, the condoms automatically roll off the mandrels. A machine shapes and trims the ring of latex at the base of each condom.

Tumbling

6 Next, the condoms are put in a tumbling machine, where they are coated with talc or another similar powder to prevent the rubber from sticking to itself.

Testing

7 After a curing period of several days, the condoms are sampled by batch and tested for leaks and strength. The first such test is the inflation test, in which the condom is filled with air until it bursts. Condoms are required to stretch beyond 1.5 cubic feet, about the size of a watermelon, before bursting. This test is considered most important because the elasticity of the condom keeps it from tearing during inter-course.

8 In the water-leakage test, the condom is filled with 10 ounces (300 ml) of water and inspected for pin-sized holes by rolling it along blotter paper.

9 Condoms are also tested electronically. This involves mounting each condom on a charged stainless steel mandrel. The mandrel is passed over by a soft, conductive brush. If pin holes are present, a circuit will be established with the mandrel, and the machine will automatically reject the condom.

Packaging

10 Condoms that have successfully passed these tests are rolled by a machine. Rolling the condom makes it easier to package and use. Lubricant and spermicide may be applied by a metering pump just before the top wrap is added in the foiling process.

Quality Control

Condoms are classified as Class II Medical Devices. According to the Medical Device Amendments of 1976 of the FDA, the FDA is required to inspect each condom manufacturing plant at least once every two years. All electrical and mechanical equipment must be impeccably maintained. Condom-dipping machines are designed to operate continuously; if they remain idle, their mechanisms can get clogged and rust. During any downtime, partially cured compound cannot be left in the dip tank because it could contaminate future production.

All condoms sold in the U.S. must comply to specifications that were voluntarily developed by condom manufacturers and adopted by the FDA. Condom measurements can range from 5.8-7.8 inches (150-200 mm) in length, 1.8-2.1 inches (47-54 mm) in width, 0.001-0.003 inches (0.03-0.09 mm) in thickness (although most condoms range between 0.002 and 0.0024 inches), and the weight cannot exceed 0.07 ounces (2 grams). Additionally, physical characteristics must include a minimum tensile strength of 15,000 pounds psa and elongation before breakage of 625%.

The FDA reviews U.S. company records and spot checks batches for cracking, molding, drying, or sticking latex. The organization also tests every lot of imported condoms. Upon sampling, lots will not pass inspection if they reveal greater than 4% failure with respect to the above dimensions, 2.5% failure with respect to tensile strength and elongation, and 0.4% failure due to leakage.

Here list the main process of condom making, each factory has their own improvement of the technology, so they are always a little different with each others.