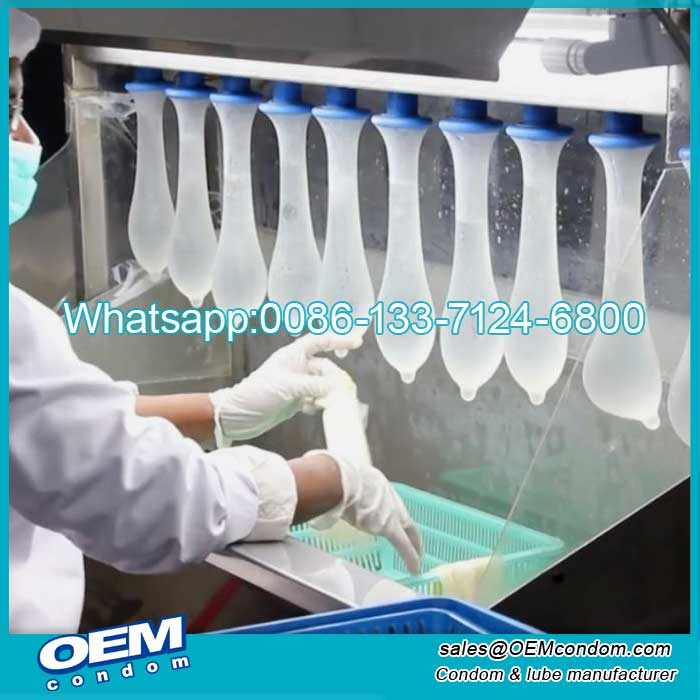

how are condoms made and tested

Condom Manufacturing flowchart

if you interested in the condom production, pls open the above button to check the condom making process, it listed all the details in the production.

The condoms are sampled by batch and tested for leaks and strength. The first such test is the inflation/Burst test, in which the condom is filled with air until it bursts. Condoms are required to stretch beyond 1.5 cubic feet, about the size of a watermelon, before bursting. This test is considered most important because the elasticity of the condom keeps it from tearing during inter-course.

In the water-leakage test, the condom is filled with 10 ounces (300 ml) of water and inspected for pin-sized holes by rolling it along blotter paper. Condoms are also tested electronically. This involves mounting each condom on a charged stainless steel mandrel. The mandrel is passed over by a soft, conductive brush. If pin holes are present, a circuit will be established with the mandrel, and the machine will automatically reject the condom. These tests will make sure each condom are good quality to use and no pin hole.

As a professional condom factory, we can custom produce clients own brand condom, MOQ is only 10 000 pcs. So easy to have own brand condom, welcome inquiry us by email: [email protected]