The low material, natural rubber latex is collected from rubber trees by tapping aslant on rubber trees early every morning.

In order to remove impurities from the collected rubber, the latex is processed in centrifuge.

For our condom production, only the highest quality & premium grade latex that passed severe tests will be used for condom manufacturing.

how to make condom in factory and the manufacturing process

1 Tapping natural rubber latex from the tree

2 Mixing and Compounding Process

After receiving inspection at factory, several chemicals are compounded with the natural latex. One important technical aspect of condom manufacturing is the ability to adjust the compounded chemicals in accordance with different conditions of latex.

Then, the latex and chemicals are heated and vulcanized to enhance strength, elasticity. In this way, the low material for condom manufacturing is produced.

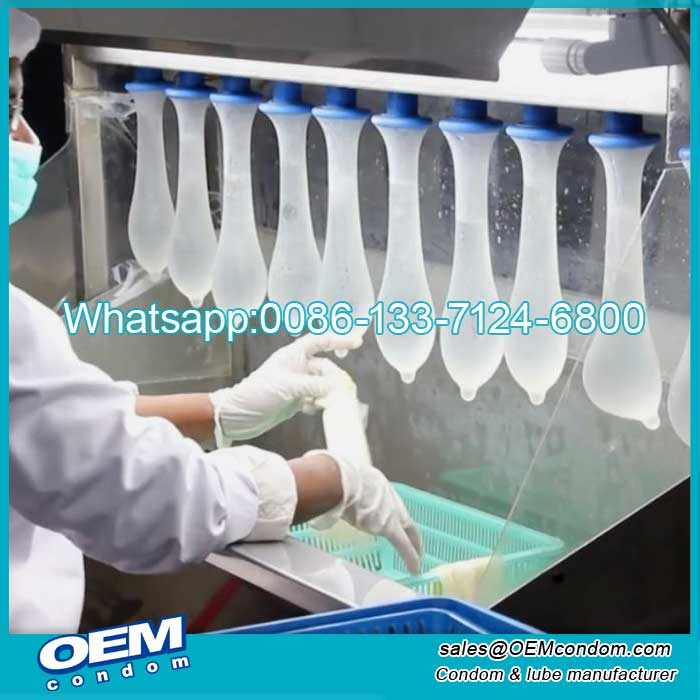

3 Latex Dipping Process

Glass dipping molds move into latex tank. Milky low material sticks to the surface of the glass molds. Then the coated glass molds moved to drying room. In order to assure consistent stability and strength, the dipping and drying process is repeated at least twice. Condoms are taken off from glass molds. Then you’ll see the shape of condom that you know well.

The process environment is automatically controlled and latex in dipping tank is inspected periodically.

4 Pin-hole Testing Process

The manufactured condoms are tested through electric conductivity using the insulation characteristic of rubber.

Even an invisible hole can be detected, when the condom is placed on the testing machines. Then condoms are rolled up automatically.

5 Foil wrapper Packing Process

Each rolled condom is lubricated and foiled one by one.

Also on this stage sampling test is done and non-conforming product is rejected.

6 Packing Process

Final condoms are packed into consumer small boxes. Each packet is weight checked.

Samples are selected at random for final inspection. Some severe tests are waiting for the finished condom products. Only lot passing the final inspection can be shipped to clients hand.

Welcome visit our condom production workshop, hope you have more chance to see how condom produced from latex liquid, and use condom as protection tool. Or if you has chance to build own condom brand, we also can help you.

CONDOM MANUFACTURING condom manufacturing, condom manufacturing process, how to make condom at home

Enquiry Form ( we will get back you as soon as possible )

Maybe you like also

Categories

- LATEX CONDOM (247)

- Flavored Condoms (9)

- Thin Condom (80)

- Large Size Condom (9)

- Small Condoms (18)

- Textured condom (19)

- Contoured condom (6)

- Dotted condom (5)

- Striped Condom (2)

- Flared Condom (4)

- Long Love Condom (13)

- Anal Condom (3)

- Female Condom (50)

- Vegan Condom (9)

- ALIEN CONDOMS (77)

- Spike Condom (23)

- Lollipop Condom (3)

- Finger Condom (8)

- Cup Condom (0)

- spiky condom (1)

- Special Condom (24)

- Novelty Condoms (19)

- NEW CONDOM (225)

- Dental Dam/Latex Sheet (5)

- Polyurethane condom (139)

- polyurethane condom supplier (45)

- Non Latex Condom (84)

- Polyisoprene Condom (18)

- CONDOM MANUFACTURING (197)

- BRAND CONDOM (261)

- polyurethane condom brands (25)

- Durex brand condom (9)

- Custom Condom (175)

- Mango brand condom (7)

- Romeo Condom (6)

- CONDOM NEWS (278)

- PERSONAL LUBRICANT (75)

- Water Intimate Lubricant (46)

- Warming Lube (3)

- Fruity Edible Lubricant (5)

- Anal lube (7)

- Sachets Lubricant (6)

- Delay Spray (5)

- Uncategorized (0)

Tags